Hybrid Ecopelican: hybrid technology for cleaner waters

A sustainable and efficient solution for waste collection in port and coastal areas

In a global context where the protection of the marine environment has become a priority, the Hybrid Ecopelican emerges as an innovative technological solution that combines sustainability, operational efficiency, and ecological commitment.

Designed and built by AISTER, this hybrid vessel is specifically engineered to carry out cleaning tasks in ports, estuaries, and inland waters, with the goal of removing floating solid waste and actively contributing to the preservation of aquatic ecosystems.

Its compact design, advanced propulsion system, and operational equipment make it a versatile tool—ideal for addressing today’s challenges in marine waste management.

Technical specifications

Technical design and hybrid propulsion system

The Hybrid Ecopelican is a 12.5-metre vessel with a 2.48-metre beam, built entirely from marine-grade aluminium—a lightweight, corrosion-resistant, and low-maintenance material.

This alloy provides the hull with high durability while ensuring a non-sinkable structure, ideal for prolonged operations under demanding conditions. Its shallow draught of just 0.80 m allows easy manoeuvring in shallow waters, making it particularly useful in ports, narrow access areas, or urban river environments.

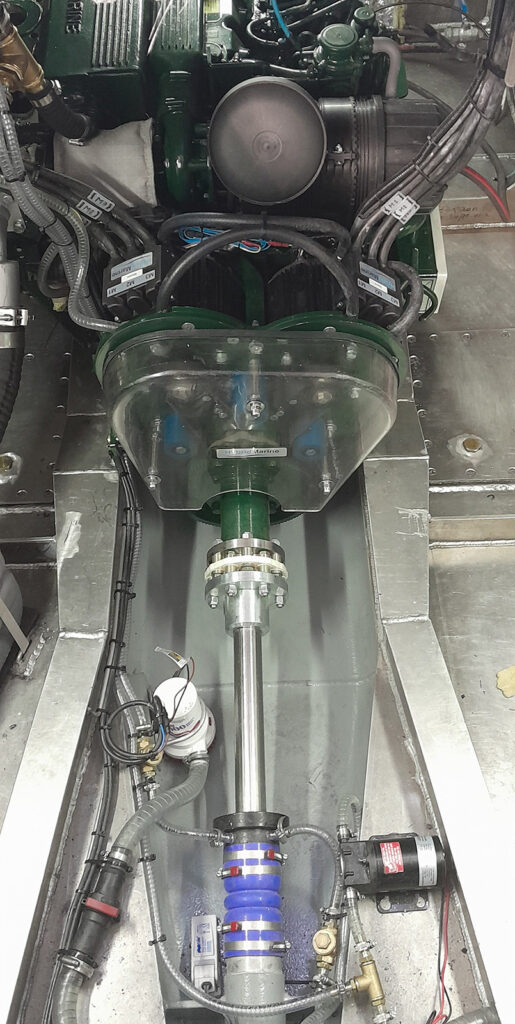

The vessel’s standout feature is its parallel hybrid propulsion system. Equipped with a 74 kW diesel engine and a 20 kW electric motor powered by an 80 kWh lithium battery, it allows seamless switching between modes based on operational requirements. It can operate in full-electric mode during sensitive manoeuvres or in environmentally protected zones, minimising noise and pollutant emissions. This capability not only enhances energy performance but also contributes to a lower environmental footprint.

Operational equipment and waste collection channel

The waste collection system is optimised for maximum efficiency thanks to its innovative bow design. Two lateral hydraulic arms are deployed to form an internal waste channel—an open space between the hull sides that guides water flow and debris towards the central collection system. This channel functions as a dynamic intake “mouth”, effectively capturing plastics, wood, and other pollutants and directing them to a conveyor that deposits the waste into an onboard container.

The vessel also features an auxiliary hydraulic outlet designed for optional equipment such as a skimmer for hydrocarbon recovery or a high-pressure washer for cleaning the vessel or external facilities.

A suction mode with a sliding nozzle connected to the propeller enables precise work in difficult-to-access areas or where semi-submerged waste is present.

Habitability, control and panoramic view

The telescopic cabin offers full 360º visibility, ensuring complete control of operations, improved safety, and better manoeuvrability. The cabin is retractable to facilitate land transport without the need for disassembly on standard trailers.

Inside, the helm console centralises all the necessary controls for propulsion and navigation, along with systems for ballast control, the hydraulic system, radio communications, navigation instruments, bilge pumps, and lighting.

The rear of the cabin features a bench for crew rest, and the port side includes a small storage area for tools and accessories.

Port maintenance with environmental commitment

The Hybrid Ecopelican is not just a functional vessel—it represents a new approach to tackling marine pollution. Custom-designed to meet the real needs of port environments, this hybrid unit proves that operational efficiency and sustainability can go hand in hand.

With this initiative, AISTER reaffirms its commitment to innovation and environmental responsibility, offering forward-thinking solutions for cleaner seas.

![]()

![]()