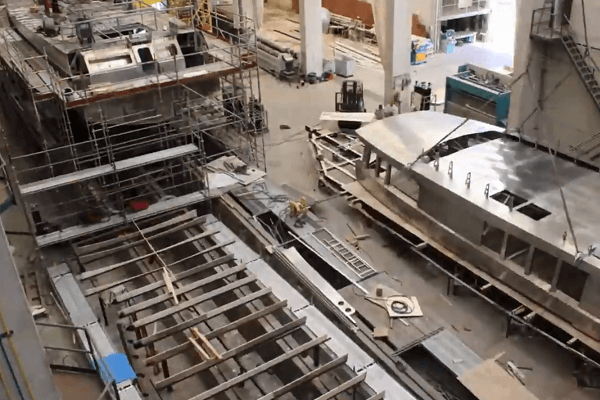

Aluminum hull and superstructure on the yacht RAFAGA for Atollvic Shipyard

This aluminum yacht, called RAFAGA, is the last vessel manufactured in Atollvic Shipyard for a private Spanish Shipowner. AISTER was the company selected by Atollvic Shipyard for the construction of the aluminum hull, the aluminum superstructure and the insulation works for the yacht.

Aluminum yacht RAFAGA on detail

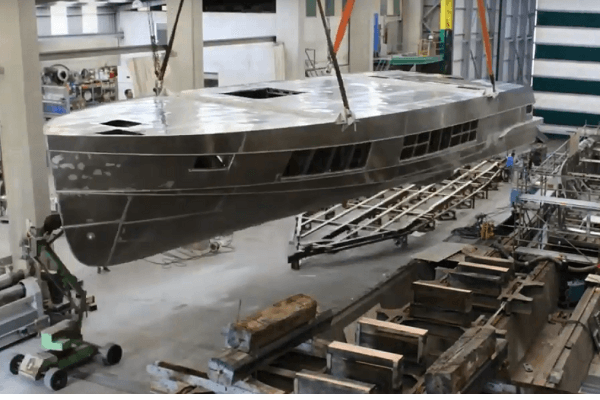

The boat has a length of 23.26 m, a beam of 6.13 m and a hull and aluminum superstructure. This material stands out for its mechanical properties such as lightness, durability and high structural strength. In its construction, our team used alloys 5083, ideal for the marine environment.

In addition, the hull of the aluminum yacht that we have built has been designed by the company Barracuda Yacht Design and stands out for its compact and robust shapes, which allows it to navigate anywhere, and for its smooth and uniform finishes, to maintain the aesthetic of the yacht.

In this way, RAFAGA has become the flagship of Atollvic Shipyard because it is very novel and exclusive since the most usual thing is to use this material in larger boats.

Forms and general arrangement

The hull of this aluminum yacht of 23.26 m is compact and robust, to navigate anywhere although it will have its usual base of operations in the Levante area.

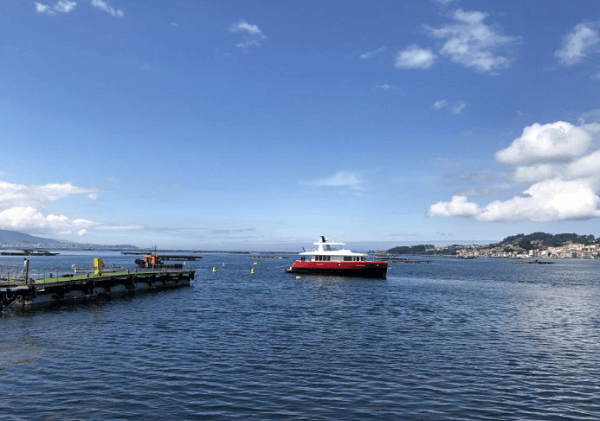

The access to the vessel is easy and comfortable, without obstacles and also has elevated handrails for greater safety of the crew travelling on board.

The ship has high and panoramic windows in the superstructure but also in the main hull.

Another of its most notable features is that this aluminum yacht allows easy mobility around it. The crew can enjoy on board as many comforts as at home safely and comfortably for the duration of the trip as in AISTER we have made the insulation of the hull for maximum comfort by eliminating the noises and vibrations of the motor navigation.

Propulsion and Navigation

The RAFAGA aluminum yacht is powered by two MAN 16 engines in a 6-cylinder line and 800 HP each. In addition, the structural tanks have been installed in-situ.

One of the most important requirements of the project was the use of lightweight thicknesses during the construction of the hull so that the boat could reach up to 1500 nautical miles at cruising speeds of 18 knots although the maximum speed of this aluminum yacht is 22 knots. To achieve this, during the painting, we search smooth and light surfaces complying with the requirements of this type of boats.

The aluminum yacht RAGAFA has become the flagship of Atollvic shipyards and, in its construction have participated an average of 50 workers and eight companies of the naval sector, specializing in different jobs, including AISTER.

Related news: The Howorths, Atollvic, Youtube