The European Union has launched its Zero Emissions 2050 strategy and the maritime sector has a lot of progress to make to achieve climate neutrality. At the same time, we find ourselves in a context of escalating fuel costs. It is undoubtedly time to consider new propulsion systems. At Aister we have 10 years’ experience in electric and hybrid propulsion boats. What are these options? Which is best for my boat? How do I know which one is right for me?

The International Maritime Organisation (IMO) has set the theme “New technologies for greener shipping” for the year 2022. The aim is to raise awareness of the technologies that will help the maritime sector move towards decarbonisation. There are still technologies to be developed, such as hydrogen, but systems such as electric and hybrid propulsion are already a reality and an option to be taken into account. The data from the latest IPCC report on the state of the climate leave no room for doubt: we must act now. And the COP20, the great summit on climate change that the United Nations is holding in November in Glasgow, points in the same direction. The maritime sector is starting to take the first steps, and the political environment, with support articulated to this end, is also favourable.

What is electric propulsion?

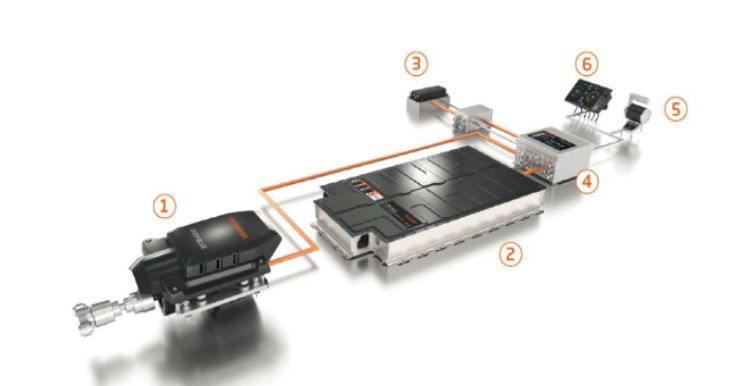

In electric propulsion or battery boats, the energy is stored in lithium batteries that are recharged in port. The electric motor is simpler than a diesel or petrol engine, both from the point of view of installation and maintenance; it takes up less space in engine rooms; they are totally “eco-friendly” and almost completely reduce the noise generated by the propulsion system. The energy cost of running on electricity is about three times cheaper than diesel.

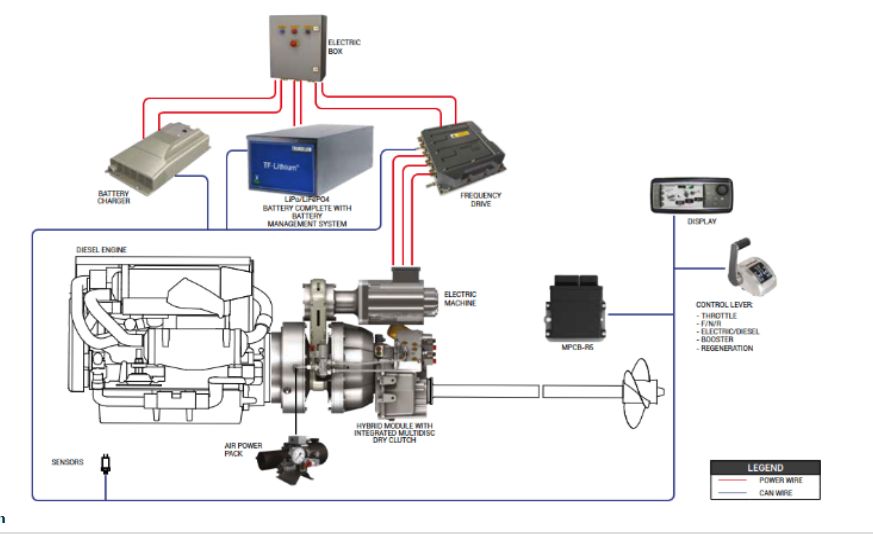

What is hybrid propulsion?

In this case, the electric power engine is combined with a combustion engine. There is the option of recharging the batteries while the boat sails with the combustion engine.

This propulsion system is ideal for vessels that have two very different operating ranges and require a very high power level, in which the diesel engine would be used, and a relatively low power level, in which it would be powered by the electric motor.

I want to change but I don’t know which one to choose, hybrid or electric.

The doubts of shipowners in this field are many and justified. Research in the energy field – both in engines and in energy storage and generation systems – is advancing and opening up new avenues and solutions. Keeping abreast of all energy innovations requires a technical team that constantly monitors them. But in addition, each vessel is unique, due to its characteristics and its operation, so it is ideal to analyse each project in detail to advise the owner on the solution that best suits their needs.

Opting for one propulsion system or another requires a detailed study of the energy needs of the boat. Aister’s technical department is committed to the most effective solutions with the technology available on the market.

Benefits beyond costs

The reduction in fuel costs is immediately reflected in the operating account of the vessel incorporating an electric propulsion system or a hybrid propulsion system, but this is only one of the advantages to be added:

- Less noise and vibrations in the environment.

- Lower or zero emissions of CO2, NOx, SOx, etc.

- The risk of environmental pollution from possible fuel spills is reduced.

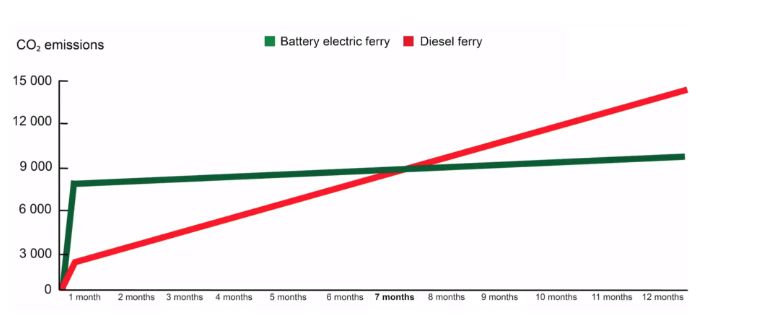

A study in Norway analysed the consumption of twin ferries connecting the two sides of the fjords. The research focused on the ships’ emissions from the time of construction of the units to recycling and their environmental impact. The conclusion reached is that the emissions generated in the procurement of raw materials, manufacture of the batteries, construction of the vessels and operation of the vessels over 20 years is initially higher in the electric ferry, up to the point when the vessel starts operating. Thereafter, the battery-powered unit, considering that the energy with which it is recharged comes from renewable sources, reaches its environmental break-even point with the diesel-powered ferry after 7 months. In other words, after 7 months, the electric-powered vessel has compensated for the higher emissions derived from the manufacture of the lithium batteries and in the 20 years of operation of the ship, 134,000 tonnes of CO2 are saved per unit.

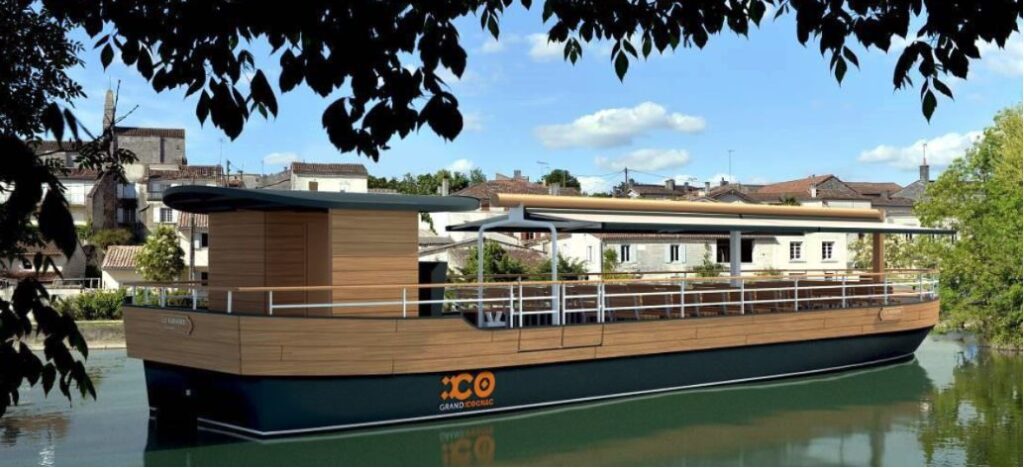

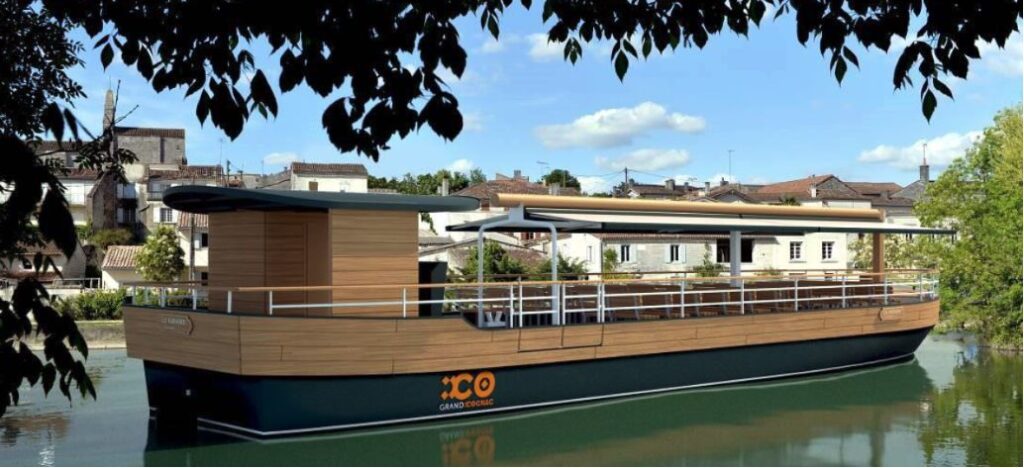

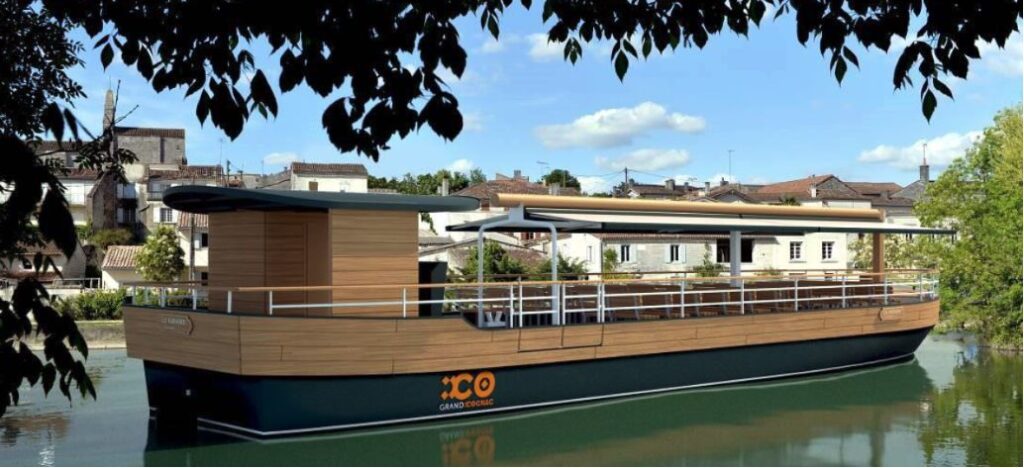

At Aister we are fully convinced that it is time to make the change. From the Juan de Omar, the first ship built by Aister with electric propulsion ten years ago and operating in the Canal de Castilla to the present day, the technological progress has been considerable. We already have on the table projects for two 20-metre hybrid passenger ships for the Charente river in France and we are fully involved in the transformation and electrification of passenger ships, port work boats, mussel auxiliary vessels and fishing boats in the Vigo estuary; Greenbay Project. The race is unstoppable and our company is strongly committed to electric and hybrid propulsion systems.

más información

más información