The private initiative of AISTER Shipyard, in collaboration with the Galician Shipbuilding Cluster Association (Aclunaga), the Galician Automotive Technology Centre (CTAG) and the Port Authority of Vigo, has launched the “Green Bay project”, an ambitious plan that seeks to electrify shipping in the Vigo estuary and create an industrial ecosystem that provides technologies and components to local shipyards.

The objective is to eliminate CO2 emissions from commercial activity in the waters of the Vigo estuary, whether from port activities, passenger traffic or aquaculture vessels. Once this model has been developed, AISTER wants to lead the environmental transition in European coastal areas.

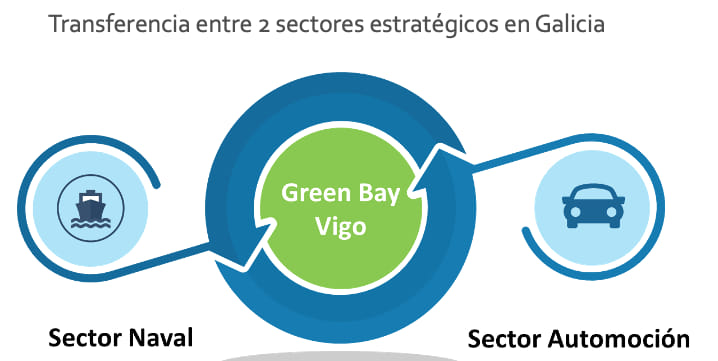

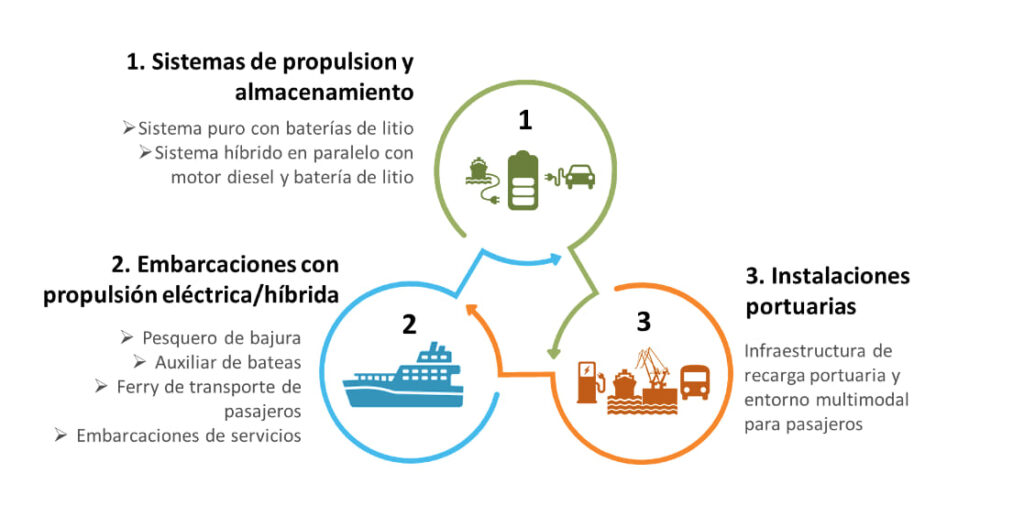

For this project, synergies will be established between the shipbuilding experience of the northwest Spain industry, and the technological development of the Galician automotive industry, more advanced in the field of batteries and vehicle autonomy. Vigo is the Galician core of the automotive industry, with the presence for more than 60 years of the Stellantis factory, the only one in Europe with two production lines, and a conglomerate of more than 200 auxiliary companies and technology centers.

In addition to the electrification of the ship and the supply of components, “Green Bay” will also focus on the installation of battery recharging points in port. The development of this technology therefore involves not only the ship operator, but also the ports Authority, as well as the energy suppliers who will have to offer solutions adapted to the needs of the users.

To tackle this electrification project, AISTER has focused on navigation within the Vigo Inland waters and has identified the vessels where it is most feasible to apply this technology. Fish farming or inland passenger traffic would be candidates for full electrification, due to their planned and recurrent routes. Vessels such as tugboats, pilot boats and other workboats, could incorporate hybrid propulsion, as they require greater power and autonomy at specific times.

The work of “Green Bay” goes beyond the coast, aiming to integrate with electric public transport in the city of Vigo, to achieve an origin-destination experience free of polluting emissions.

Official presentation of the project

The “Green Bay” project was presented at the Rectoral de Cobres Hotel, an idyllic place in the heart of the Vigo estuary. The event, organised by AISTER, with the collaboration of Aclunaga, CTAG and the Port Authority of Vigo, and brought together the port community, from passenger operators, port pilots, tugboats, moorers and representatives of other activities such as aquaculture.

AISTER’s sales and business development director, Ignacio de Francisco, was the master of ceremonies and in charge of presenting the conference. The first speaker was Óscar Gomez, manager of Aclunaga, who pointed out that “what has been pursued from the beginning is the development of alternatives in a complex area such as the Vigo estuary”, and recalled that “given the European Union regulations, we must adapt” and that the solution is that both shipyards and service and infrastructure providers and operators “have logical solutions”. All of this involves achieving lower consumption and less pollution from vessels.

Javier Rasilla, managing director of AISTER, explained that the first experience of the shipyard with this technology was 10 years ago with the project of a passenger ship for the Canal de Castilla, being pioneers in Galicia. Rasilla pointed out that after starting to work with the technical director, Francisco Pita, they contacted the Galician Automotive Cluster (CEAGA), which showed its support and recommended adding the Galician Automotive Technology Centre (CTAG) on board. Together with Aclunaga, they applied to the Ministry for Ecological Transition’s call for proposals. “This is not the future, it is the past”, said Rasilla in reference to the fact that Scandinavian countries are already operating 100% electric ships.

“The objective is clear: to develop capacities in the local industry to be able to manufacture this type of vessels with cutting-edge technologies brought from the automotive industry.

Francisco Pita, technical director of AISTER, explained the difference between hybrid and electric propulsion. “Why electric?” he asked the audience rhetorically. Pita highlighted four points in favour. Firstly, the cost of energy, which in the case of diesel is much higher than electricity “especially when we are charging on a night rate”. In addition to this, there is less maintenance due to the reduction in the number of mechanical elements, noise and pollutant emissions.

AISTER’s technical director pointed out that a study conducted in Norway concluded that comparing an electric ferry and a diesel ferry, the emission reduction is significant: 134 000 tonnes of CO2.

Pita outlined the main barriers to entry in the use of electric propulsion technology and contingency measures to address them. A possible lack of batteries in the middle of the estuary, a rare phenomenon, could be alleviated with emergency batteries or a small auxiliary group that would allow the electric propulsion engines to be driven. Another barrier is the high investment in batteries. Among the possible options is battery leasing, so that the shipowner does not assume the risk. The operator would only pay per use, and the moment the battery’s performance drops, it could be replaced. AISTER’s technical director pointed out that the aim is not to have batteries that last 10 years, because in 5 years this technology will have improved.

Hydrogen was the subject of a chapter of its own. Pita pointed out that a hydrogen ship would actually have electric propulsion. The ship would maintain batteries to store the energy produced by the fuel cell and a hydrogen tank would be added. The main benefit of this gas is that it weighs 10 times less than diesel fuel, creating new construction possibilities. If this technology becomes established, the design of the ship will have to take into account that the battery room can easily be converted into a hydrogen storage room.

Eduardo Rivero, laboratory manager at CTAG, explained that the automotive sector is making progress in price competitiveness, although it is working on challenges such as the materials used for batteries, which are “scarce” and where “the supply chain can break”.

Pilar González, head of the Institutional Promotion and Territorial Cooperation department at the CDTI, explained the different lines of finance, either for the “Green Bay” project and the sub-projects arising from this initiative could apply. Among other funds, she mentioned the Next Generation funds and the calls for business innovation missions. Fernando Guldrís, director of IGAPE, explained that the Ministry of Industry is working on calls for proposals for the so-called “Strategic Projects for Economic Recovery and Transformation” or PERTE. The first will be aimed at the automotive industry and will enable the requirements and aid for companies to be measured.

Victor Solano, New Construction Client Manager at Lloyd’s Register, explained that the vessels within the “Green Bay” project would comply with the Merchant Navy regulations classified as inland waters, in addition to having to apply IMO rules. Solano differentiated between two class levels: working vessels (pilots, fish farming boats, tugs) and passenger vessels, which have different regulations for both machinery and passengers. The Lloyd’s Register representative reviewed the services offered by the classification society, including error, safety and reliability simulations.

From the Port Authority of Vigo, Carlos Botana, head of the Sustainability Department, explained that 76% of the port’s carbon footprint comes from ships during manoeuvres. The objective, within the “Green Bay” project, is to encourage ships entering the port to take their energy from the terrestrial electrical network or to connect to the outlets which will be developed in this project, that is to say a ZERO emissions port infrastructure.

más información

más información